Found the training to be very informative. Seb from the head office has always been very responsive and happy to assist with any queries and support using the system and always gives us updates on newly available courses. Many thanks!

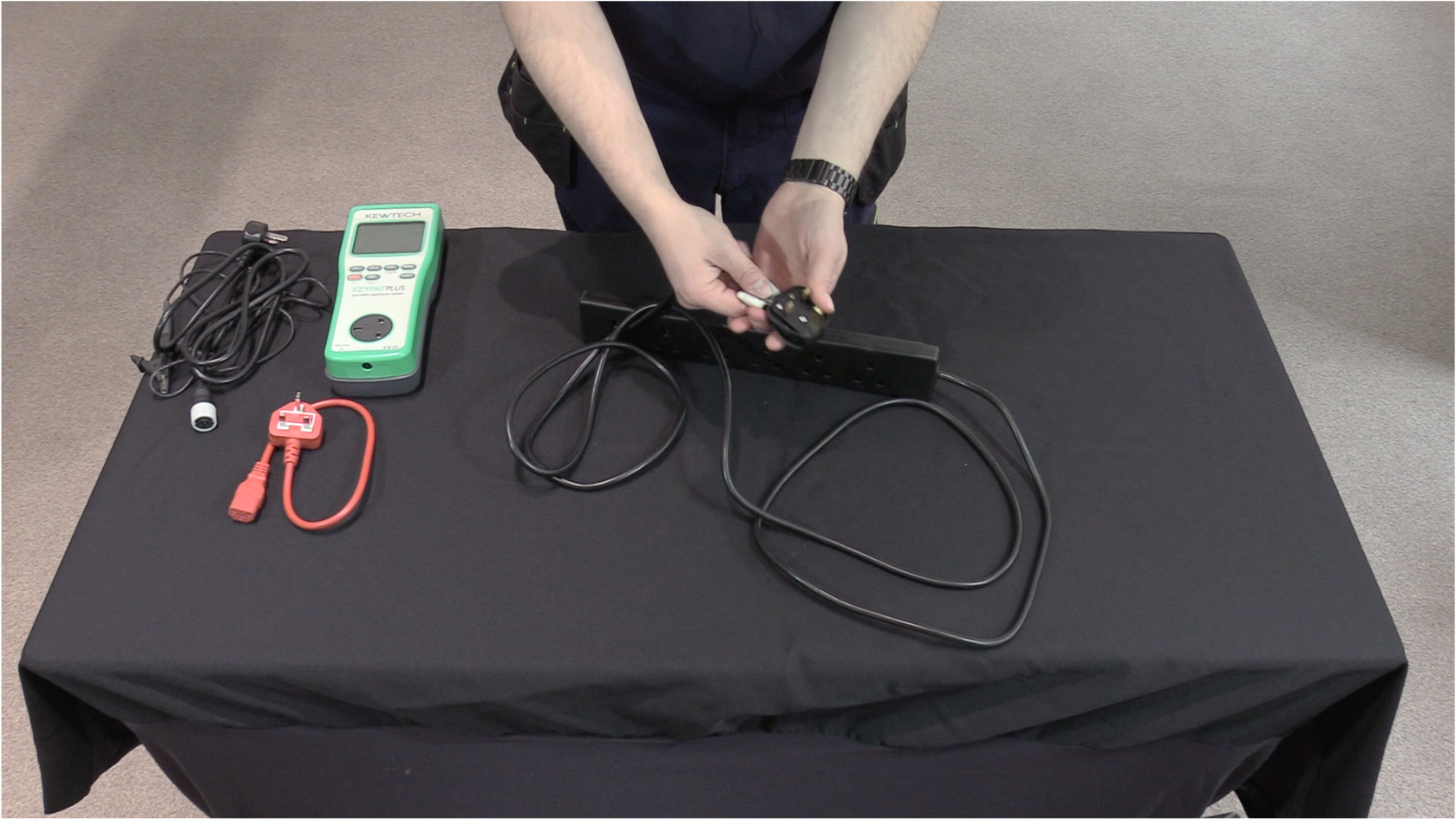

Measure performance with on-the-job skills assessments